Carbide Drill Bits For Hardened Steel

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Carbide Drill Bits For Hardened Steel. We look forward to cooperating with you.With competitive prices and reliable delivery services, we are expecting become your long-term partner in China.

Model:DTZ-4D

Send Inquiry

Product Description

Carbide Tipped: Carbide hammer drill bits are typically made with a hardened steel body that features a carbide tip or insert at the cutting end. The carbide tip is extremely hard and wear-resistant, allowing it to handle the abrasive and dense nature of masonry materials.

Reinforced Design: The carbide tip provides the necessary hardness to penetrate through hard materials, while the steel body of the drill bit provides durability and strength to withstand the impacts from the hammer drill.

Impact Resistance: These drill bits are specifically designed to handle the percussion forces produced by hammer drills or rotary hammers. The impact action helps break up the material as the drill bit rotates, allowing for efficient drilling in tough surfaces.

Versatility: While primarily used for masonry materials, some carbide hammer drill bits can also drill into other materials like wood or metal, although they might not be as efficient as purpose-built bits for those materials.

Cooling and Lubrication: When drilling into masonry materials, carbide hammer drill bits can generate a significant amount of heat. It's important to use water or a suitable lubricant as a cooling agent to prevent the bit from overheating and becoming damaged.

Various Sizes and Shapes: Carbide hammer drill bits come in a range of sizes and shapes, allowing you to choose the right bit for the hole diameter you need.

Safety Considerations: When using carbide hammer drill bits, wear appropriate personal protective equipment, such as safety glasses and hearing protection. The use of a hammer drill or rotary hammer can create substantial vibration and noise.

Proper Technique: To achieve the best results and prolong the life of the drill bit, use proper drilling techniques, including applying steady pressure and allowing the drill bit to do the work without forcing it excessively.

When selecting carbide hammer drill bits, consider the type of material you're drilling into, the required hole diameter, and the hammer drill or rotary hammer you'll be using. Follow the manufacturer's recommendations for usage, maintenance, and safety precautions to ensure effective and safe drilling operations.

Carbide drill bits for hardened steel are specialized cutting tools designed to efficiently drill holes in materials that are exceptionally hard, like hardened steel. Hardened steel is a tough and abrasive material that can quickly wear down conventional high-speed steel (HSS) drill bits. Carbide drill bits, with their superior hardness and wear resistance, are the preferred choice for drilling into such challenging materials. Here's more information about these drill bits:

Carbide Material: Carbide drill bits for hardened steel are typically made from solid carbide, which is a composite of tungsten carbide particles and a binder material (often cobalt). This combination results in an extremely hard cutting edge capable of cutting through hardened steel without becoming dull too quickly.

Geometry: These drill bits often have specialized geometries and point designs that are optimized for cutting into hard materials. The geometry helps to efficiently remove material while reducing cutting forces and heat buildup.

Heat Resistance: Carbide's ability to withstand high temperatures makes these drill bits suitable for drilling hardened steel, which generates a lot of heat during the drilling process.

Coolant or Lubrication: When drilling into hardened steel, coolant or lubrication is usually recommended to manage heat and extend the tool life. Proper cooling prevents the drill bit from overheating and ensures consistent cutting performance.

High Cutting Speeds: Carbide drill bits can be used at higher cutting speeds compared to HSS drill bits, resulting in faster drilling operations and improved productivity.

Precision and Accuracy: These drill bits are capable of producing precise and accurate holes with tight tolerances, which is crucial when working with hardened steel in industries like manufacturing and engineering.

Various Sizes: Carbide drill bits for hardened steel come in various sizes to accommodate different hole diameters and applications.

Safety Considerations: Drilling into hardened steel can generate a significant amount of heat and sparks. Ensure you're wearing appropriate personal protective equipment, including safety glasses and protective clothing.

When using carbide drill bits for hardened steel, follow the manufacturer's recommendations for cutting speeds, feed rates, coolant/lubrication usage, and safety precautions. Additionally, pay attention to the drill bit's condition and replace it if you notice signs of wear or decreased performance. Proper tool maintenance and adherence to best practices will help you achieve successful drilling operations in hardened steel and other challenging materials.

Reinforced Design: The carbide tip provides the necessary hardness to penetrate through hard materials, while the steel body of the drill bit provides durability and strength to withstand the impacts from the hammer drill.

Impact Resistance: These drill bits are specifically designed to handle the percussion forces produced by hammer drills or rotary hammers. The impact action helps break up the material as the drill bit rotates, allowing for efficient drilling in tough surfaces.

Versatility: While primarily used for masonry materials, some carbide hammer drill bits can also drill into other materials like wood or metal, although they might not be as efficient as purpose-built bits for those materials.

Cooling and Lubrication: When drilling into masonry materials, carbide hammer drill bits can generate a significant amount of heat. It's important to use water or a suitable lubricant as a cooling agent to prevent the bit from overheating and becoming damaged.

Various Sizes and Shapes: Carbide hammer drill bits come in a range of sizes and shapes, allowing you to choose the right bit for the hole diameter you need.

Safety Considerations: When using carbide hammer drill bits, wear appropriate personal protective equipment, such as safety glasses and hearing protection. The use of a hammer drill or rotary hammer can create substantial vibration and noise.

Proper Technique: To achieve the best results and prolong the life of the drill bit, use proper drilling techniques, including applying steady pressure and allowing the drill bit to do the work without forcing it excessively.

When selecting carbide hammer drill bits, consider the type of material you're drilling into, the required hole diameter, and the hammer drill or rotary hammer you'll be using. Follow the manufacturer's recommendations for usage, maintenance, and safety precautions to ensure effective and safe drilling operations.

Carbide drill bits for hardened steel are specialized cutting tools designed to efficiently drill holes in materials that are exceptionally hard, like hardened steel. Hardened steel is a tough and abrasive material that can quickly wear down conventional high-speed steel (HSS) drill bits. Carbide drill bits, with their superior hardness and wear resistance, are the preferred choice for drilling into such challenging materials. Here's more information about these drill bits:

Carbide Material: Carbide drill bits for hardened steel are typically made from solid carbide, which is a composite of tungsten carbide particles and a binder material (often cobalt). This combination results in an extremely hard cutting edge capable of cutting through hardened steel without becoming dull too quickly.

Geometry: These drill bits often have specialized geometries and point designs that are optimized for cutting into hard materials. The geometry helps to efficiently remove material while reducing cutting forces and heat buildup.

Heat Resistance: Carbide's ability to withstand high temperatures makes these drill bits suitable for drilling hardened steel, which generates a lot of heat during the drilling process.

Coolant or Lubrication: When drilling into hardened steel, coolant or lubrication is usually recommended to manage heat and extend the tool life. Proper cooling prevents the drill bit from overheating and ensures consistent cutting performance.

High Cutting Speeds: Carbide drill bits can be used at higher cutting speeds compared to HSS drill bits, resulting in faster drilling operations and improved productivity.

Precision and Accuracy: These drill bits are capable of producing precise and accurate holes with tight tolerances, which is crucial when working with hardened steel in industries like manufacturing and engineering.

Various Sizes: Carbide drill bits for hardened steel come in various sizes to accommodate different hole diameters and applications.

Safety Considerations: Drilling into hardened steel can generate a significant amount of heat and sparks. Ensure you're wearing appropriate personal protective equipment, including safety glasses and protective clothing.

When using carbide drill bits for hardened steel, follow the manufacturer's recommendations for cutting speeds, feed rates, coolant/lubrication usage, and safety precautions. Additionally, pay attention to the drill bit's condition and replace it if you notice signs of wear or decreased performance. Proper tool maintenance and adherence to best practices will help you achieve successful drilling operations in hardened steel and other challenging materials.

Carbide Drill Bits For Hardened Steel Specification

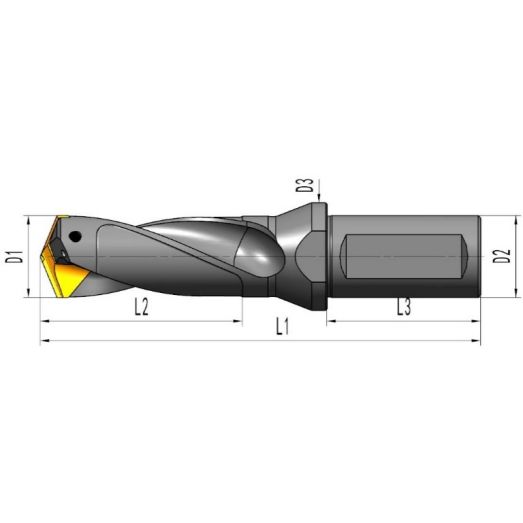

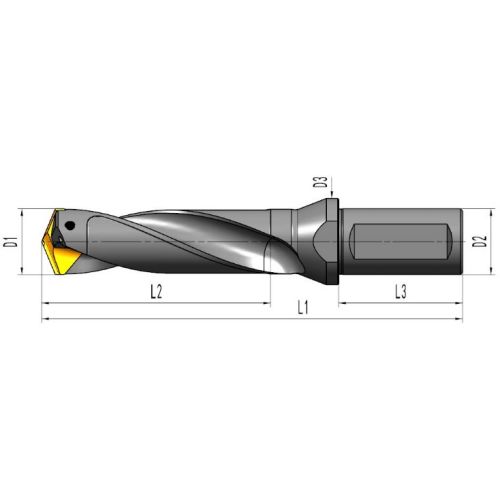

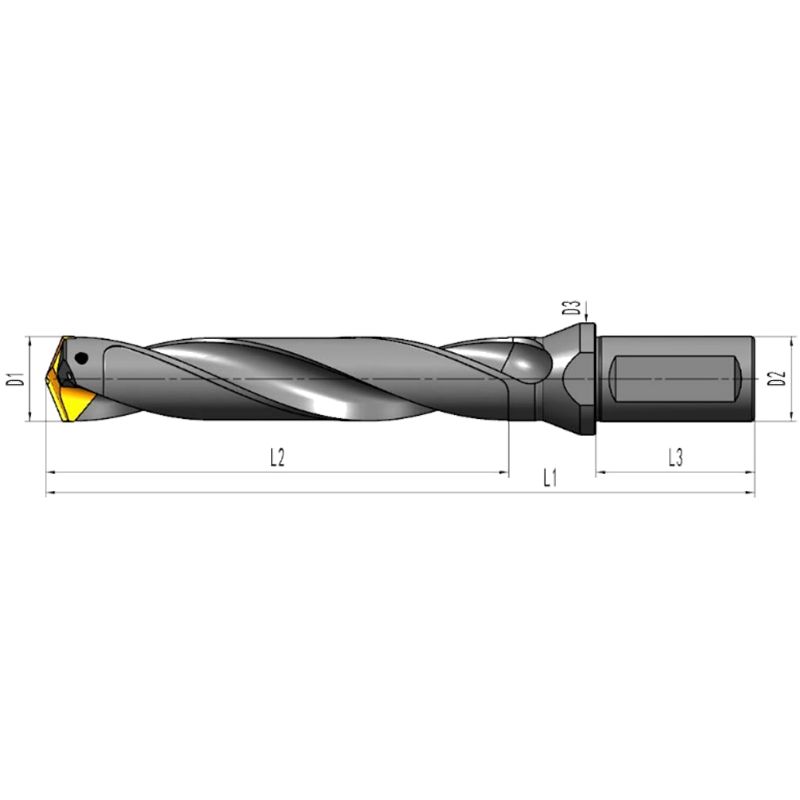

| specifications |

Adjustable blade diameter range D1 |

Knife handle size | annex | |||||

| L1 | L2 | L3 | D2 | D3 | screw | wrench | ||

| DTZ-10/1049-4D-C16 | 10.00~10.49 | 111 | 47 | 48 | 16 | 24 | M2.0x9.5 | 6IP |

| DTZ-10/1099-4D-C16 | 10.00~10.99 | 111 | 47 | 48 | 16 | 24 | ||

| DTZ-11/1149-4D-C16 | 11.00~11.49 | 115 | 51 | 48 | 16 | 24 | ||

| DTZ-11/1199-4D-C16 | 11.00~11.99 | 115 | 51 | 48 | 16 | 24 | ||

| DTZ-11/1249-4D-C16 | 12.00~12.49 | 120 | 55 | 48 | 16 | 24 | M2.5x10.9 | 7IP |

| DTZ-12/1299-4D-C16 | 12.00~12.99 | 120 | 55 | 48 | 16 | 24 | ||

| DTZ-13/1349-4D-C16 | 13.00~13.49 | 124 | 59 | 48 | 16 | 24 | ||

| DTZ-13/1399-4D-C16 | 13.00~13.99 | 124 | 59 | 48 | 16 | 24 | ||

| DTZ-14/1449-4D-C20 | 14.00~14.49 | 134 | 63 | 50 | 20 | 28 | M3.0x12.8 | 8IP |

| DTZ-14/1499-4D-C20 | 14.00~14.99 | 134 | 63 | 50 | 20 | 28 | ||

| DTZ-15/1549-4D-C20 | 15.00~15.49 | 138 | 67 | 50 | 20 | 28 | ||

| DTZ-15/1599-4D-C20 | 15.00~15.99 | 138 | 67 | 50 | 20 | 28 | ||

| DTZ-16/1649-4D-C20 | 16.00~16.49 | 143 | 72 | 50 | 20 | 28 | ||

| DTZ-16/1699-4D-C20 | 16.00~16.99 | 143 | 72 | 50 | 20 | 28 | ||

| DTZ-17/1749-4D-C20 | 17.00~17.49 | 148 | 77 | 50 | 20 | 28 | M3.0x14.7 | |

| DTZ-17/1799-4D-C20 | 17.00~17.99 | 148 | 77 | 50 | 20 | 28 | ||

| DTZ-18/1849-4D-C20 | 18.00~18.49 | 154 | 81 | 50 | 20 | 28 | M4.0x16.7 | 15IP |

| DTZ-18/1899-4D-C20 | 18.00~18.99 | 154 | 81 | 50 | 20 | 28 | ||

| DTZ-19/1949-4D-C20 | 19.00~19.49 | 159 | 86 | 50 | 20 | 28 | ||

| DTZ-19/1999-4D-C20 | 19.00~19.99 | 159 | 86 | 50 | 20 | 28 | ||

| DTZ-20/2099-4D-C25 | 20.00~20.99 | 174 | 92 | 56 | 25 | 35 | ||

| DTZ-21/2199-4D-C25 | 21.00~21.99 | 178 | 96 | 56 | 25 | 35 | ||

| DTZ-22/2299-4D-C25 | 22.00~22.99 | 183 | 101 | 56 | 25 | 35 | ||

| DTZ-23/2399-4D-C25 | 23.00~23.99 | 187 | 105 | 56 | 25 | 35 | ||

| DTZ-24/2499-4D-C25 | 24.00~24.99 | 196 | 110 | 56 | 25 | 35 | M5.0x20.6 | 20IP |

| DTZ-25/2599-4D-C32 | 25.00~25.99 | 207 | 114 | 60 | 32 | 42 | M5.0x22.6 | |

| DTZ-26/2699-4D-C32 | 26.00~26.99 | 211 | 118 | 60 | 32 | 42 | ||

| DTZ-27/2799-4D-C32 | 27.00~27.99 | 216 | 123 | 60 | 32 | 42 | ||

| DTZ-28/2899-4D-C32 | 28.00~28.99 | 220 | 127 | 60 | 32 | 42 | ||

| DTZ-29/2999-4D-C32 | 29.00~29.99 | 225 | 132 | 60 | 32 | 42 | ||

| DTZ-30/3099-4D-C32 | 30.00~30.99 | 229 | 136 | 60 | 32 | 42 | ||

Hot Tags: Carbide Drill Bits For Hardened Steel, Manufacturers, Suppliers, China, Factory, Customized, Quality

Related Categories

Deep Hole Drilling

WC Drill Bits

SP Drill Bits

WD Drill Bits

880 Indexable Insert Drills

Drill Bit with Center

Tungsten Steel Drill Bits

High Speed Steel Drill Bits

Dowel Drill Bits

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy

English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  한국어

한국어  Malay

Malay  Dansk

Dansk  Suomi

Suomi  Pilipino

Pilipino  Türkçe

Türkçe  العربية

العربية  ελληνικά

ελληνικά  Latine

Latine