Solid Carbide Drill Bits

Solid carbide drill bits are cutting tools used for drilling holes in various materials. These drill bits are made entirely from a single piece of carbide material, which is a composite of tungsten carbide particles and a binder material (typically cobalt). This carbide material is extremely hard and wear-resistant, making solid carbide drill bits well-suited for machining tasks that require precision and durability.

Model:DTZ-6D

Send Inquiry

Product Description

Solid carbide drill bits are cutting tools used for drilling holes in various materials. These drill bits are made entirely from a single piece of carbide material, which is a composite of tungsten carbide particles and a binder material (typically cobalt). This carbide material is extremely hard and wear-resistant, making solid carbide drill bits well-suited for machining tasks that require precision and durability. Here are some key features and benefits of solid carbide drill bits:

Hardness and Wear Resistance: Carbide is significantly harder than high-speed steel (HSS), which is commonly used in traditional drill bits. This hardness allows solid carbide drill bits to cut through tough materials, such as hardened steel, stainless steel, cast iron, and various alloys, without quickly dulling.

Durability: The wear-resistant nature of solid carbide drill bits contributes to their extended tool life. They can maintain their cutting performance over a longer period of time compared to HSS drill bits.

High Speeds and Feeds: Solid carbide drill bits can withstand higher cutting speeds and feeds due to their hardness. This results in faster drilling operations and increased productivity.

Accuracy and Precision: These drill bits are known for their ability to produce accurate and precise holes with tight tolerances. They are commonly used in applications where hole location and size are critical.

Versatility: While solid carbide drill bits excel in hard and abrasive materials, they can also be used for drilling holes in softer materials like plastics, wood, and composites.

Coolant and Lubrication: Depending on the material being drilled and the specific application, coolant or lubrication might be necessary to manage heat generation and extend tool life.

Reduced Vibration: The rigidity and hardness of solid carbide contribute to reduced vibration during drilling, resulting in improved hole quality and less stress on the tool.

Various Geometries: Solid carbide drill bits come in various geometries, such as twist drills, center drills, spot drills, and more, each designed for specific drilling applications.

It's important to note that while solid carbide drill bits offer numerous advantages, they are more brittle than some other materials. Care should be taken to avoid lateral forces that could cause the drill bit to break. Additionally, proper maintenance, such as keeping the drill bit cool and sharp, will help ensure optimal performance.

When using solid carbide drill bits, always follow the manufacturer's recommendations regarding cutting speeds, feed rates, lubrication, and safety practices. Choosing the appropriate drill bit for the material and application is crucial for achieving the best results.

Hardness and Wear Resistance: Carbide is significantly harder than high-speed steel (HSS), which is commonly used in traditional drill bits. This hardness allows solid carbide drill bits to cut through tough materials, such as hardened steel, stainless steel, cast iron, and various alloys, without quickly dulling.

Durability: The wear-resistant nature of solid carbide drill bits contributes to their extended tool life. They can maintain their cutting performance over a longer period of time compared to HSS drill bits.

High Speeds and Feeds: Solid carbide drill bits can withstand higher cutting speeds and feeds due to their hardness. This results in faster drilling operations and increased productivity.

Accuracy and Precision: These drill bits are known for their ability to produce accurate and precise holes with tight tolerances. They are commonly used in applications where hole location and size are critical.

Versatility: While solid carbide drill bits excel in hard and abrasive materials, they can also be used for drilling holes in softer materials like plastics, wood, and composites.

Coolant and Lubrication: Depending on the material being drilled and the specific application, coolant or lubrication might be necessary to manage heat generation and extend tool life.

Reduced Vibration: The rigidity and hardness of solid carbide contribute to reduced vibration during drilling, resulting in improved hole quality and less stress on the tool.

Various Geometries: Solid carbide drill bits come in various geometries, such as twist drills, center drills, spot drills, and more, each designed for specific drilling applications.

It's important to note that while solid carbide drill bits offer numerous advantages, they are more brittle than some other materials. Care should be taken to avoid lateral forces that could cause the drill bit to break. Additionally, proper maintenance, such as keeping the drill bit cool and sharp, will help ensure optimal performance.

When using solid carbide drill bits, always follow the manufacturer's recommendations regarding cutting speeds, feed rates, lubrication, and safety practices. Choosing the appropriate drill bit for the material and application is crucial for achieving the best results.

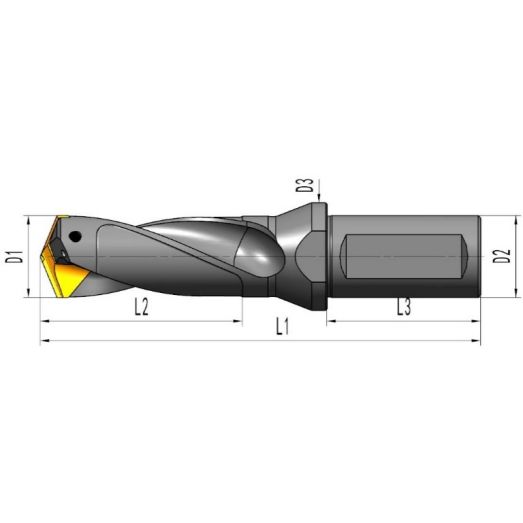

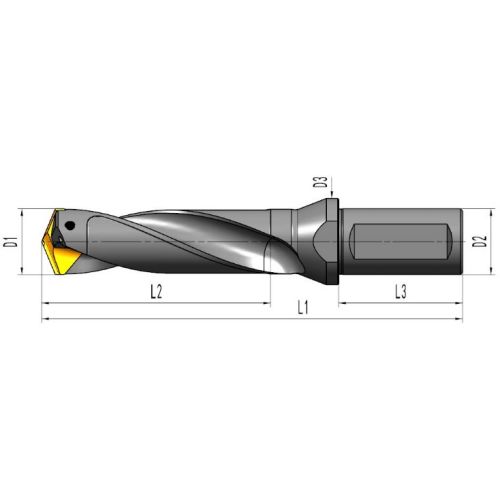

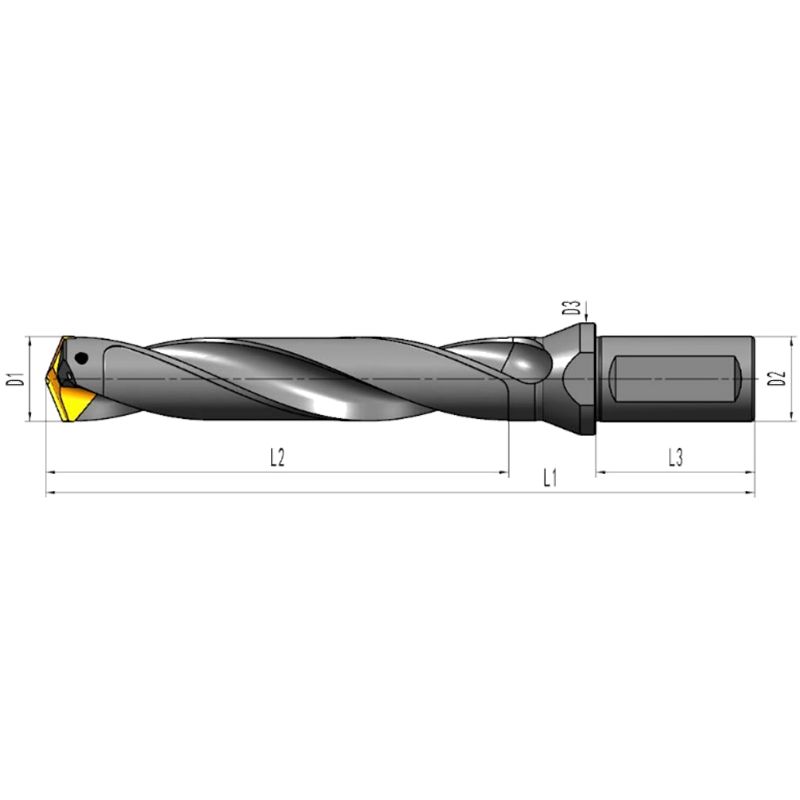

Solid Carbide Drill Bits Specification

| specifications |

Adjustable blade diameter range D1 |

Knife handle size | annex | |||||

| L1 | L2 | L3 | D2 | D3 | screw | wrench | ||

| DTZ-10/1049-6D-C16 | 10.00~10.49 | 131 | 67 | 48 | 16 | 24 | M2.0x9.5 | 6IP |

| DTZ-10/1099-6D-C16 | 10.00~10.99 | 131 | 67 | 48 | 16 | 24 | ||

| DTZ-11/1149-6D-C16 | 11.00~11.49 | 137 | 73 | 48 | 16 | 24 | ||

| DTZ-11/1199-6D-C16 | 11.00~11.99 | 137 | 73 | 48 | 16 | 24 | ||

| DTZ-11/1249-6D-C16 | 12.00~12.49 | 144 | 79 | 48 | 16 | 24 | M2.5x10.9 | 7IP |

| DTZ-12/1299-6D-C16 | 12.00~12.99 | 144 | 79 | 48 | 16 | 24 | ||

| DTZ-13/1349-6D-C16 | 13.00~13.49 | 150 | 85 | 48 | 16 | 24 | ||

| DTZ-13/1399-6D-C16 | 13.00~13.99 | 150 | 85 | 48 | 16 | 24 | ||

| DTZ-14/1449-6D-C20 | 14.00~14.49 | 162 | 91 | 50 | 20 | 28 | M3.0x12.8 | 8IP |

| DTZ-14/1499-6D-C20 | 14.00~14.99 | 162 | 91 | 50 | 20 | 28 | ||

| DTZ-15/1549-6D-C20 | 15.00~15.49 | 168 | 97 | 50 | 20 | 28 | ||

| DTZ-15/1599-6D-C20 | 15.00~15.99 | 168 | 97 | 50 | 20 | 28 | ||

| DTZ-16/1649-6D-C20 | 16.00~16.49 | 175 | 104 | 50 | 20 | 28 | ||

| DTZ-16/1699-6D-C20 | 16.00~16.99 | 175 | 104 | 50 | 20 | 28 | ||

| DTZ-17/1749-6D-C20 | 17.00~17.49 | 182 | 111 | 50 | 20 | 28 | M3.0x14.7 | |

| DTZ-17/1799-6D-C20 | 17.00~17.99 | 182 | 111 | 50 | 20 | 28 | ||

| DTZ-18/1849-6D-C20 | 18.00~18.49 | 190 | 117 | 50 | 20 | 28 | M4.0x16.7 | 15IP |

| DTZ-18/1899-6D-C20 | 18.00~18.99 | 190 | 117 | 50 | 20 | 28 | ||

| DTZ-19/1949-6D-C20 | 19.00~19.49 | 197 | 124 | 50 | 20 | 28 | ||

| DTZ-19/1999-6D-C20 | 19.00~19.99 | 197 | 124 | 50 | 20 | 28 | ||

| DTZ-20/2099-6D-C25 | 20.00~20.99 | 214 | 132 | 56 | 25 | 35 | ||

| DTZ-21/2199-6D-C25 | 21.00~21.99 | 220 | 138 | 56 | 25 | 35 | ||

| DTZ-22/2299-6D-C25 | 22.00~22.99 | 227 | 145 | 56 | 25 | 35 | ||

| DTZ-23/2399-6D-C25 | 23.00~23.99 | 233 | 151 | 56 | 25 | 35 | ||

| DTZ-24/2499-6D-C25 | 24.00~24.99 | 244 | 158 | 56 | 25 | 35 | M5.0x20.6 | 20IP |

| DTZ-25/2599-6D-C32 | 25.00~25.99 | 257 | 164 | 60 | 32 | 42 | M5.0x22.6 | |

| DTZ-26/2699-6D-C32 | 26.00~26.99 | 263 | 170 | 60 | 32 | 42 | ||

| DTZ-27/2799-6D-C32 | 27.00~27.99 | 270 | 177 | 60 | 32 | 42 | ||

| DTZ-28/2899-6D-C32 | 28.00~28.99 | 276 | 183 | 60 | 32 | 42 | ||

| DTZ-29/2999-6D-C32 | 29.00~29.99 | 283 | 190 | 60 | 32 | 42 | ||

| DTZ-30/3099-6D-C32 | 30.00~30.99 | 289 | 196 | 60 | 32 | 42 | ||

Hot Tags: Solid Carbide Drill Bits, Manufacturers, Suppliers, China, Factory, Customized, Quality

Related Categories

Deep Hole Drilling

WC Drill Bits

SP Drill Bits

WD Drill Bits

880 Indexable Insert Drills

Drill Bit with Center

Tungsten Steel Drill Bits

High Speed Steel Drill Bits

Dowel Drill Bits

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy

English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  한국어

한국어  Malay

Malay  Dansk

Dansk  Suomi

Suomi  Pilipino

Pilipino  Türkçe

Türkçe  العربية

العربية  ελληνικά

ελληνικά  Latine

Latine